Mailbox:

info@hskcoltd.com

Mailbox:

info@hskcoltd.com

Hashimoto Precision Metal (Shenzhen) Ltd

Address: No. 25, Xinfa East Road, Xiangshan Community, Xinqiao street, Bao'an District, Shenzhen 518125, P.R.China

Tel: +86-755-27267875

Email: info@hskcoltd.com

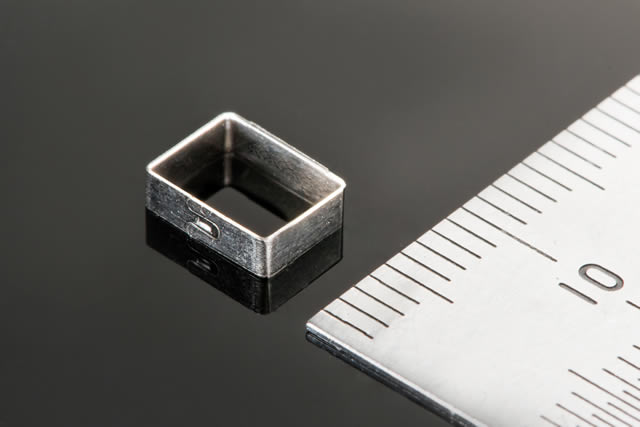

Many precision metal stamping parts are made of copper, aluminum alloy and other soft materials. These materials themselves are more delicate and expensive, so we must control technology and cost to ensure surface quality. How can we solve these problems?

When using these materials to produce precision metal stamping parts, attention should be paid to whether there is trace metal residue on the surface of the material to avoid scratches. When the burr surface is bent as the outer surface, the stamping part is easy to produce cracks and scratches, so the burr surface should be bent as the inner surface.

The fillet radius of the tooling is too small, and the formed part is easy to produce indentation. We need to polish the die and increase the fillet radius of the die, which can effectively avoid scratches. At the same time, the punch clearance should not be too small, which is easy to cause thinning and scratching. During the manufacturing process, always check the change of die clearance.

In order to make the precision metal stamping parts meet the accuracy requirements, the spring and locating pin hole on the pressing plate will produce indentation during the forming process. These factors need to be considered in the design to avoid such problems.

Hashimoto Precision Metal (Shenzhen) Ltd

Address: No. 25, Xinfa East Road, Xiangshan Community, Xinqiao street, Bao'an District, Shenzhen 518125, P.R.China

Tel: +86-755-27267875

Email: info@hskcoltd.com

Follow us

Copyright ? 2021 Hashimoto Precision Metal (Shenzhen) Ltd

Address: No. 25, Xinfa East Road, Xiangshan Community, Xinqiao street, Bao'an District, Shenzhen 518125, P.R.China

Tel: +86-755-27267875

Mailbox